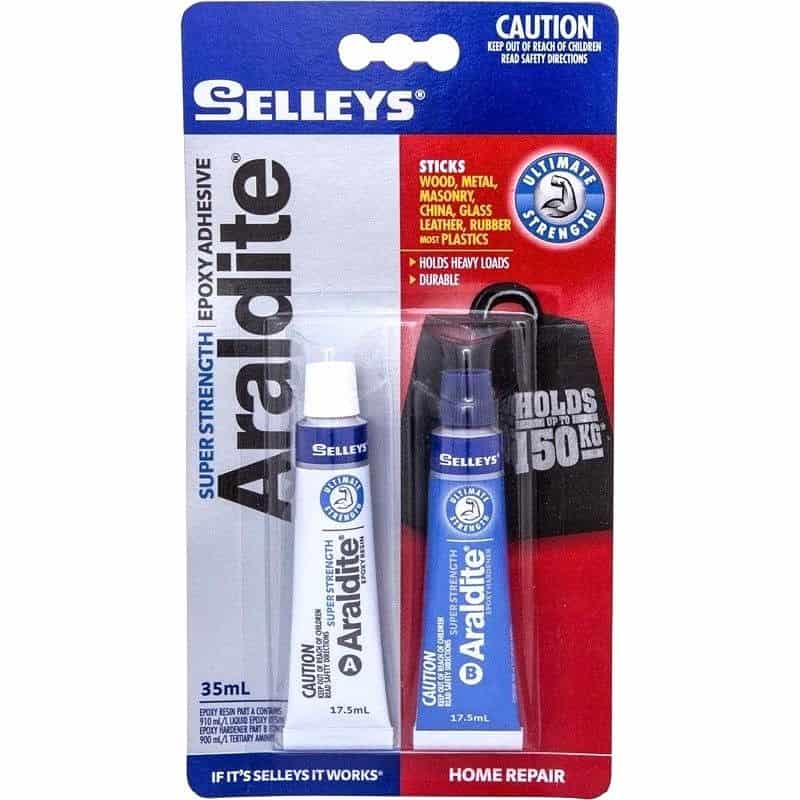

Description

A two part epoxy adhesive that bonds with maximum strength. Mixed product gels in 2 hours. Initial bonding is achieved in 6-8 hours with maximum bond strength strength after 3 days.

Features

- Araldite is stronger than other glues due to the chemical reaction of the two parts

- Bonds a variety of surfaces

- Dries Clear

- Very Strong, durable bonding

- Very high water resistance (e.g. OK for fixing tiles around pool, but not below the water line. For this use Selleys Knead it Aqua)

- Forms a rigid, durable bond

- Can be used for gap filling (surfaces need not mate closely)

- Good chemical resistance

- Heat Resistant

- Clamping is recommended to achieve a stronger bond

- Not suitable for bonding plastics such as Polypropylene and Polyethylene

- Bond strength weakens above 80 C but strength is regained when temperature drops

Appearance

- Translucent

Where can this product be used?

- Load bearing repairs

- Gluing the head back on your hammer

- Fixing loose table or chair legs.

- Bonding solid pieces of Aluminium sheeting

- Bonding timber on your boat

- Repairing splits and cracks in Cricket bats

- Bonding fibreglass sheets

- Repairing Ski’s

- Fixing Dynabolts and metal rods into concrete

What materials is this product suitable for?

- Glass

- Metal

- Wood

- Fabric

- Rigid Plastic will not bond to Polyethylene or Polypropylene plastics

- Crystal

- Leather

How to use this product

- Before applying the Araldite mixture, all surfaces MUST’be thoroughly clean and dry.

- All traces of grease, rust paint, etc. should be removed.

- For best results smooth surfaces should be roughened by mechanical abrasion after solvent cleaning.

- Onto a clean, disposable surface (e.g. polyethylene or cardboard), dispense equal volumes of Part A and Part B. Thoroughly mix together with a spatula, nail or stick. When using the tubes it is essential to use the correct mixing ratio, i.e. 1 part each

- Apply adhesive immediately to both surfaces and press together. Clamping is necessary while bond sets over 6-8 hours. Scrape off excess adhesive and wipe mixing utensils immediately.

- When using tubes, Ensure correct caps are replaced on each tube or they will harden

Handy tips

- For maximum working time, mix in small quantities. Large quantities accelerate the curing process and reduce working time.

- To extend product life replace caps immediately after use. Ensure you wipe excess from nozzle with a tissue dipped in acetone (or nail polish remover) before replacing cap.

- When using the tube variant, ensure you replace the correct cap on the correct tube. Placing the wrong cap on the wrong tube will cause the tube to harden. (lids and tubes are colour coded to help)

- Wipe off any uncured araldite with acetone or nail polish remover.

- To remove product after cure, mechanical action (scraping or sanding) is recommended. Since the product is chemically resistant solvent will NOT dissolve this product.

- To reposition the bond once cured, check that the item is heat resistant. If safe, heat the item slowly, e.g. in an oven, to at least 150oC. The product will soften and liquify slightly. Scrape off any excess then reposition the joint carefully using appropriate safety equipment. Allow the item to cool down in the correct position. The product will reharden once returned to room temperature.

- Clamping recommended for a stronger bond.

- For cleaning surfaces prior to application of adhesive, if the surface is porous, we would reccomend using Selleys Liquid Sugar Soap. If the surfact is non-porous eg glass or metal, firstly clean the surface with Methylated Spirits. If there is old difficult to remove residue such as oold paint, we recommend using paint stripper such as Selleys Kwik Strip Smart. Ensure the surface is dry before applying the product.

- A useful solvent to clean up epoxy and polyester resins BEFORE they are cured can be prepared by mixing 2 parts toluene with 1 part alcohol (eg methylated spirits or denatured alcohol).

Safety tips

- Avoid contact with the skin and eyes.

- Avoid breathing vapour.

- Do not use solvents near eyes or open wounds.

- In case of contact with eyes, flush with water for at least 15 minutes and seek medical attention.

- Non toxic when set.

- For further information refer to the Material Safety Data Sheet (MSDS).

Storage and re-use

- Ensure caps are replaced and product stored in a cool dry place.

Fast & Free Postage

Same Day Handling

30 Day Return

(07) 3268 7161

(07) 3268 7161

View Cart

View Cart

Australian Owned

Australian Owned Fast dispatch

Fast dispatch 30 Day Return Policy

30 Day Return Policy Industry Leading Support

Industry Leading Support